Sustainability in Grain, Milling, Food and Alcohol Production

Our milling, food and ethyl alcohol production facilities have proven themselves to be extraordinarily efficient in processing. The by-products of one process become the feedstock for the next, enabling us to be a zero waste facility! All of the raw material received by our facility is turned into edible, salable product consumed by humans or animals. Therefore there is no waste stream that needs to be transported and disposed of.

Power input per unit of product has steadily declined as more efficient motors and lighting fixtures were installed; labor input per unit has plummeted with the introduction of more reliable equipment and electronic controls. In these traditionally low-margin industries, sustainability is necessary for survival.

Our flour mill is much smaller than traditional flour mills thereby utilizing less utilities and creating a targeted 'craft' product specific to our customers' diverse needs. Our gluten plant uses a unique process whereby water use is greatly reduced to comparable gluten plants who utilize a 'washing' process step.

Our carbon intensity is much lower than traditional alcohol biorefineries. By utilizing multiple feedstocks for alcohol production, we are better able to navigate commodity market challenges and by creating our own power and steam onsite, we are able to be off of Alberta's carbon intense electrical grid!

Our next goal is to produce our own biogas through biodigestion of our syrup which would in turn create renewable natural gas that would power our cogeneration turbine and allow us to sell biogas and power to the provincial grid systems!

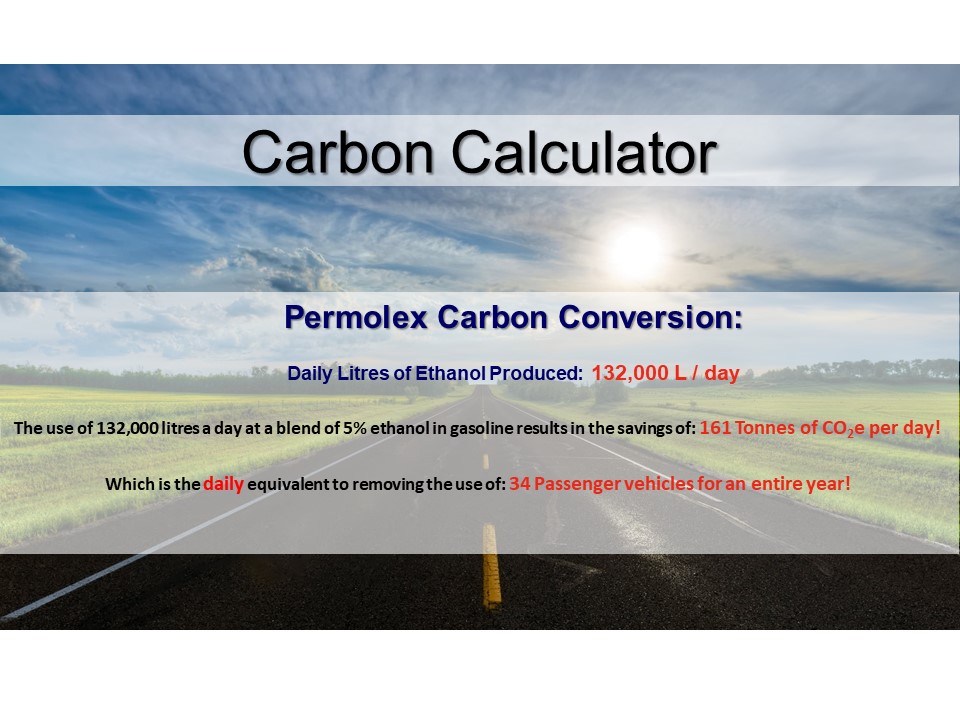

When using our Fuel Grade ethanol:

Paperless workflows when possible

Transactional efficiencies where possible

Teleconferencing to reduce travel when possible

Just-in-Time philosophy for maximum plant efficiency

FSSC Certification

State-of-the-art cleaning systems, resulting in up to 40% energy savings

Bulk flour delivery where possible for reduced packaging waste

We are committed to supporting the communities where our associates live and work

Support local charities by donating money, products, time, and services

Strong local supply chain for feedstock directly from local farmers generally with 150km of the plant

Using ethanol blended gas as a natural octane booster reduces harmful GHG’s from the atmosphere as well as fine particulate matter resulting in many health benefits.

Ethanol is a natural gas line antifreeze and our ethanol is 66% cleaner than baseline gasoline

The byproducts created from our processes are used to sustainably feed livestock and protein substitutes such as insects for animal feed!

We have switched to LEDs and other energy-efficient lighting in our offices and plants

We use variable speed drives on our motors wherever possible to improve energy efficiency.

We use our own onsite cogeneration power to create all of the steam and electricity needs for all site operations so that we are off of the Alberta coal driven, carbon intense grid.

Off specification food produced is recycled

Electronic equipment, printer & copier consumables are recycled

Containers such as totes and barrels, paper, cardboard, oil, filters, plastics, supersacks, & light bulbs recycled

Direct transfer from our mill and ethanol production area to loadouts in the same facility

Direct transfer system to packaging facility to avoid truck transport between plants

We use primarily one carrier for all incoming and outgoing products to avoid cross contamination and ensure food security

We own our bulk flour trailers to avoid cross contamination and ensure food security

We optimize the use of available space in our outbound truck deliveries to reduce the number of trucks on the road.

We consider the sustainable use of our world’s natural resources an important part of Permolex’s history,

and the key to our continued success going forward.